KimYuan’s Guide to Cut Resistance Gloves

Cut Resistance Gloves are the most competitive product line of KimYuan’s safety gloves. With KimYuan Material put into production this year, KimYuan Safety will become one of the few safety glove producers in the world to own the entire vertical production ability.

Why You Should Use Cut-Resistant Gloves

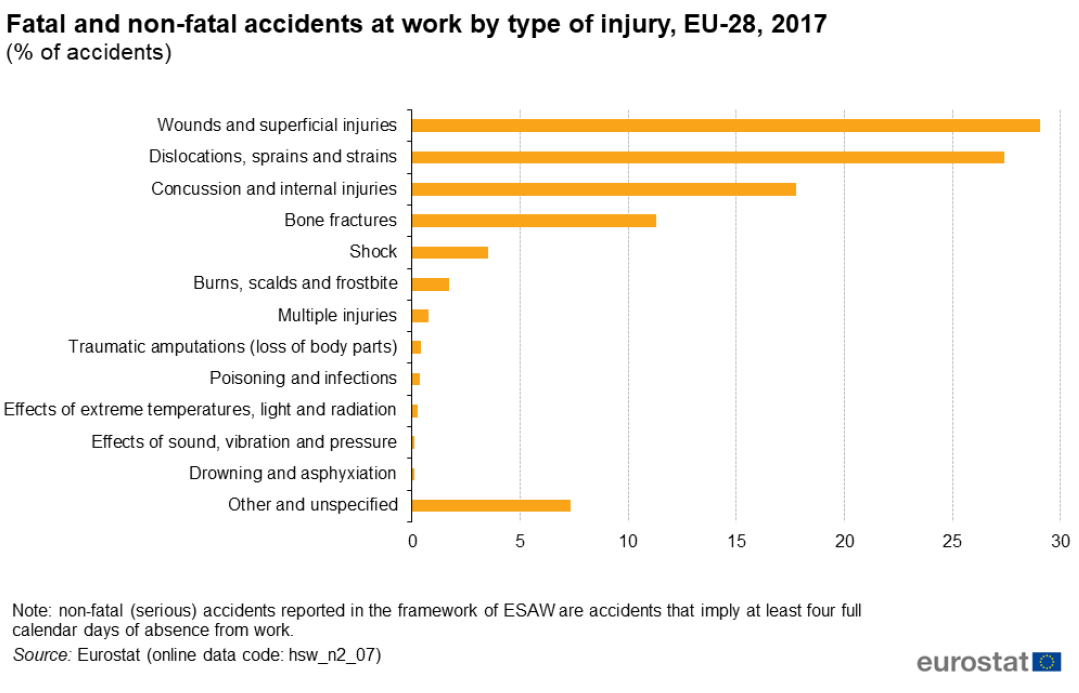

Cut-resistant gloves are designed to offer the user just that: a pair of gloves that can help to protect their hands from cuts and punctures while working with sharp tools. In 2017, an incredible 29.1% of all workplace injuries (Eurostat, 2017) in the EU were wounds and superficial injuries and your hands are the most common part of the body to be injured – over twice more likely than any other part of the body.

These injuries are a big problem for workers and businesses alike. On average, 6.6 days a year (HSE’s Health and Safety Statistics Annual report) are lost per worker through hand-related injuries, so using protective equipment should be of the utmost importance. One of the most effective ways to protect your hands is to use cut-resistant gloves, and these come in a range of styles and protection to suit easy industry and job.

What are cut-resistant gloves?

Cut-resistant gloves are manufactured from a number of different materials, but some of the most popular include:

Metal Fiber:

– Metal fiber cut-resistant gloves are made from a woven fabric that has been blended with stainless steel. This makes them highly durable while remaining flexible and comfortable for the user to wear.

HPPE:

– HPPE, or High-Performance Polyethelene, is a very flexible and lightweight glove, whilst remaining equally durable and tactile. HPPE gloves are highly abrasion resistant and cut resistant.

Dyneema:

– Dyneema is a very strong fiber that is 15 times stronger than steel. Highly durable, gloves made from Dyneema are resistant to water and chemicals without detracting from the user’s dexterity; making them suitable for a wide choice of industries.

Kevlar:

– Kevlar cut-resistant gloves provide the hand with high cut and puncture protection while remaining very flexible and comfortable to wear. Kevlar is frequently used by those who work in kitchens and high-heat environments thanks to it being a flame-resistant material.

Graphene Liner:

– Graphene Liner is a Graphene based yarn that solves the dispersibility of traditional yarns and offers flexibility at the same time. Graphene is the first 2-dimensional material discovered with only one-atom thick, so it’s the thinnest material found and is 100 times stronger than steel.

Each of these materials will typically be twisted and mixed into one roll which is then knitted into the gloves, giving them different cut-resistance levels. These gloves will be sold based on their gauge, which indicated the number of stitches per square inch and can range from seven (the heaviest) up to 18.

How are cut-resistant gloves tested?

It is important to remember that not all cut-resistant gloves are rated to the same standard. Every pair that you purchase will be rated to a certain level:

– ANSI/ISEA 105:

The ANSI rating was first introduced in 2000 by the American National Standards Institute and rates the glove based on its ability to resist cutting, puncturing, and abrasion as well as its temperature protection, flame resistance, and chemical protection. The ANSI rating was updated in 2005, allowing it to grade the globes cut resistance on a scale of 0-5, based on how much weight it takes for a straight blade to cut one inch.

– EN338:

This is the European rating for cut-resistant gloves and is based on the abrasion and tear resistance alongside the ability to withstand punctures and cuts. EN338 was updated in 2016 and gloves are rated on a scale of A-F, which is based on the number of cycles a rotating blade requires to cut through the gloves. Although it uses a number rating similar to ANSI, it is important to remember these are separate tests and not interchangeable.

Which jobs and industries require cut-resistant gloves?

No matter what industry you work in, if you are regularly using your hands and handling sharp objects or are exposed to sharp materials or extreme temperatures then protective gloves are essential.

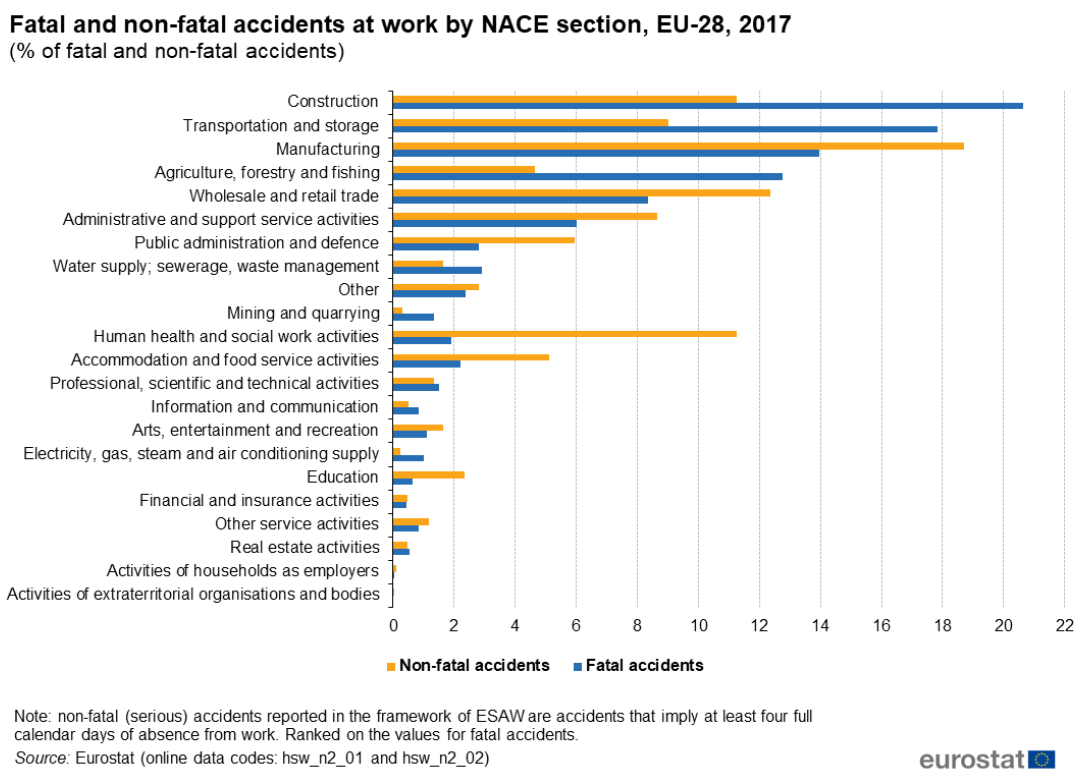

Some of the most common industries include construction, mechanics, agriculture, and engineering but equally, chefs and anyone using tools can benefit from using cut-resistant gloves. To ensure you are fully protected, then it is important to choose the right style and protection for your job. Not every worker will require the highest graded glove, it will depend on the weight, maneuverability, comfort, and of course protection required to safely and securely carry out your job.

How to choose from different cut-resistant gloves?

Despite from different materials, cut-resistant gloves are classified by two dimensions: cut-resistant level and number of gauges. Generally speaking, works with higher cut hazard potentials require higher cut level, and works that need precision operations require high gauges. With additional features such as thermal, oil resistance, chemical resistance, and heat resistance, please contact us for further advice.